Episode #1: a collective adventure between land and sea, from prototype to production of Mytiprotect

"We come from two different worlds, the world of industry and us as mussel famers, there will be a clash of cultures but not at all, Auray Plast understood the urgency of the product."

Laurent Lesiourd

Edulimer produces Bouchot mussels and is based in the Bay of Arguenon in Saint-Cast-le-Guildo in the Côtes d’Armor. Like many mussel farmers, Guillaume Bouchonneau, the director of Edulimer, suffered significant losses (around 60%) on marketable mussels during the summer of 2020. The spat (young mussels in the larval or embryonic state) had also not been spared during this period, resulting in low seeding with significant repercussions on volumes.

Edulimer observed in 2021 the highest predation observed in the Bay of Arguenon for decades.

For the past two years, professionals in the sector have been observing the increasing presence of a new, more voracious predator in the bay: the sea bream. This added to the already present predators (crabs and seagulls). Sea bream are increasingly present on the Emerald Coast due to climate change. In one night, a school of sea bream can destroy an entire line of Bouchot mussels.

Edulimer has to react urgently to save its production and develop an efficient anti-predation system. Guillaume Bouchonneau, head of Edulimer, contacted Auray Plast to develop and industrialize an emergency spacer system to save the 2021 season.

Wich solution ?

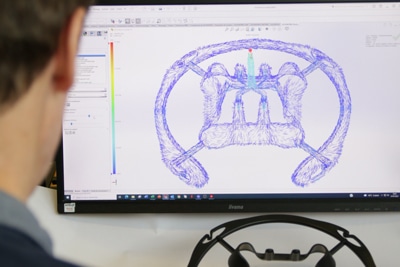

The chosen solution is a net spacer made of recycled polypropylene. Sleeves were placed on the stakes, but this system had a drawback: the net rubbed against the mussels and hindered the growth of the spat. Moreover, the solution was not effective enough against predators. The spacer allows both fixing the sleeve to the stake without staples or plastic ties and keeping the sleeve away from the stake to avoid hindering the mussels and preventing predation. The system needed to be flexible to easily fit a wide range of square stakes and strong enough to withstand the weather. The design office Expert Solution 3D came up with the design, and Auray Plast conducted sizing and material tests to ensure that this technical part perfectly met the expectations of mussel farmers with the aim of industrialization.

What are the results?

Thanks to its 3D printers, Auray Plast produced a first prototype. This prototype allowed validating the sizing of the part and the raw materials used to meet multiple constraints. Then, a mold was designed by a French mold maker in less than 7 weeks. Auray Plast industrialized the part by injecting 100,000 spacers to equip the different stakes of several mussel farmers. The rapid development allowed Edulimer to carry out tests in real conditions. The initial results are promising: Edulimer observed that the stakes were much more populated and that the spat were more developed. The spacer was named Mytiprotect and has allowed various mussel farmers in the Bay of Arguenon to save their production of the 2021 season.

Discover the services of our design office

Our design office offers its expertise to provide you with technical services:

- Conducting injection mold tests

- Designing prototypes using 3D printing

- Verification and material testing for injection

- Creating grippers

- Rheological simulation and injectability.

Discover other episodes