Injection of plastic parts

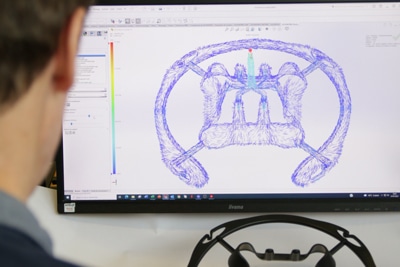

Our machine fleet consists of 24 injection molding machines, ranging from 30 to 350 tons. 75% of them are electric. They allow for the perfect control of production parameters for the production of your most precise parts (for example medical applications).

Injection of technical parts for various application areas.

Mastery of injection of TPU thermoplastic parts.

Injection of small parts in large volumes and with restrictive tolerances.

Design of high-performance technical seals for various applications.

Robotization & agility: discover our 100% automated line

Continuous improvement and investment are necessary for the sustainability of our industry and its economic competitiveness. We have automated a production line by combining various functions on a single machine. The unloading of several components, their control, cutting, assembly, and strapping are done with the help of 4 Fanuc 6-axis robots and 4 vision cameras.

Various sectors of activity

Medical sector

Auray Plast works alongside actors from the medical field by mastering the injection of flexible TPE plastics. Our fully automated processes guarantee a protected environment.

Agricultural sector

The design and mass production of dynamic or static sealing joints for hydraulic cylinders is the historical business sector of Auray Plast.

Boating

Due to our geographical location and also out of passion, we work for the boating industry. Our expertise allows us to advise our clients on issues of sealing, resistance to UV or saltwater environments.

Industry

Industrial applications require expertise in design (geometry, material suitable for the application) and then in the mass production of parts.

Materials

PA – PE – TPU – TPE

TPV – HYTREL – ABS Polyamide

PP – POM – PA6 – ASA

Finishes

Cutting

Thermal stabilization

Finishing

Processes

Injection

Assembly

Auray Plast launches production of parts for a sustainable dishwasher

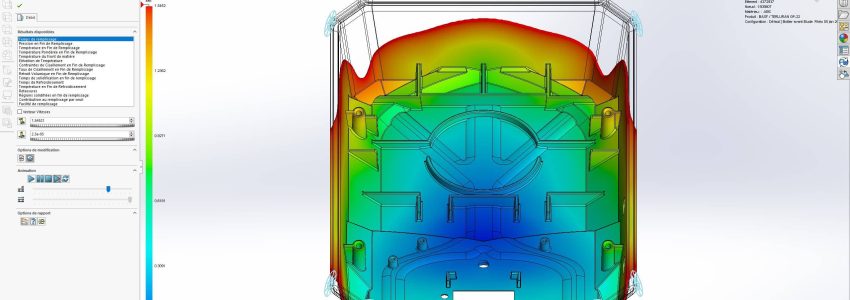

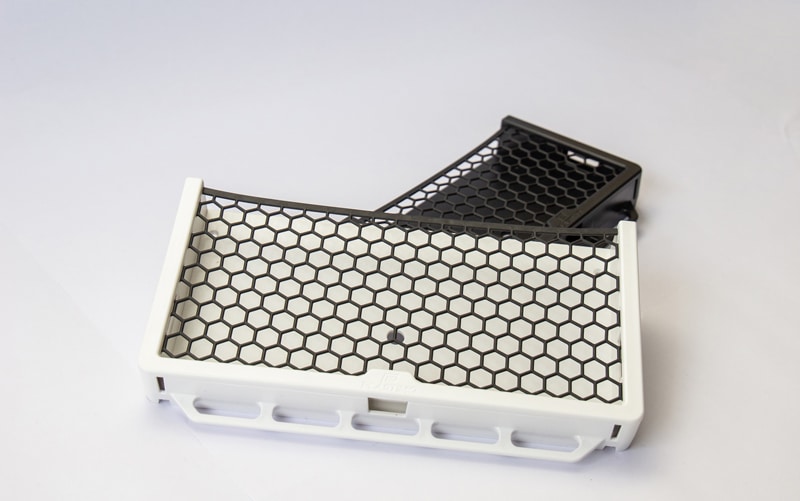

Auray Plast, an expert in thermoplastic injection molding, takes a strategic turn with the industrialization of some fifty parts for a sustainable dishwasher. This project, part of a circular economy approach, marks a key stage in the diversification of our business.

For 50 years, we have been developing sealing solutions for technical applications. Today, we’re broadening our scope to support our growth and meet the challenges of new markets.

Discover our projects & customer experiences