Quality, Safety, Environment and Energy Commitments

Our certifications: commitments shared by all

Auray Plast holds quadruple certifications in quality, safety, environment, and energy to guarantee products that meet your specifications.

We believe that “quality is everyone’s responsibility,” so we have developed an internal training plan to ensure that each employee is trained in various quality processes as part of our continuous improvement approach.

“Quality is not a quick or temporary fix, it is a process of continuous improvement."

3 certifications for a 360° commitment

Ensuring products and services that meet our customers’ requirements through efficient metrology tools and a control laboratory.

Continuously improving working conditions with the active participation of our employees to identify hazards and reduce health risks.

Committing to sustainable development by integrating eco-design into our processes and promoting the recycling of plastic materials.

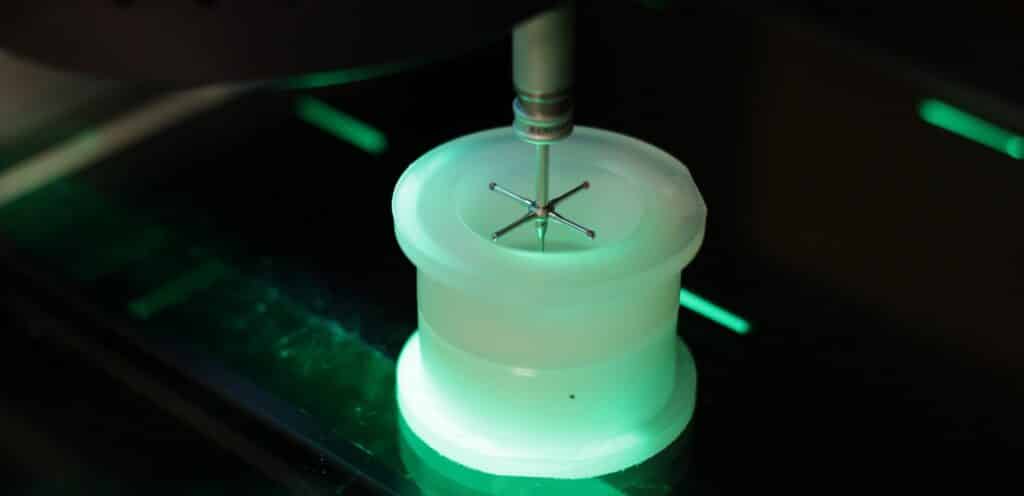

Control of incoming materials to accurately characterize the material

We have a chemical and mechanical control laboratory for the characterization of raw materials. These initial controls are essential as they allow us to verify the physicochemical properties of the materials using efficient characterization tools:

- MFI to measure the melt flow index,

- DRC to measure compression set,

- Durometer to measure hardness,

- Abrasion tester to determine the material’s abrasion rate,

- Viscosimeter to measure viscosity.

- Control of parts to perfectly match your quality standards

Control of parts to perfectly match your quality standards

Metrology is the science of measurement. It defines the principles and methods for ensuring confidence in measurements. Dimensional controls aim to validate that a products characteristics are compliant.

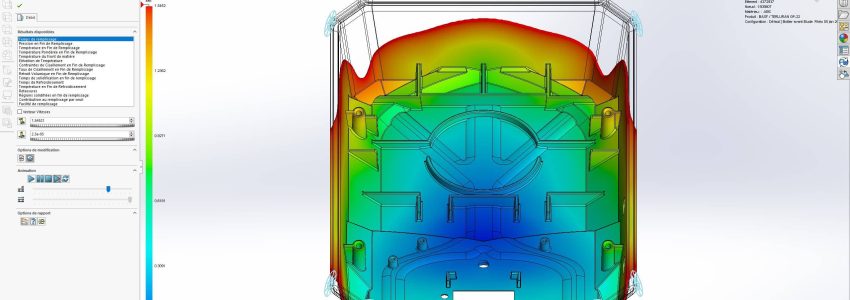

We have various instruments that allow us to perform measurements at each stage of the injection molding process, from qualification to shipment.

- CNC 300 for high-precision measurements during qualification (micron precision).

- Profile projector, micrometer, and caliper for production measurements (hundredth precision).

What concrete actions?

For the environment: prioritization of local partners, compliance with GPI (industrial plastic pellets) regulations, recycling of materials and the use of up to 80 tons/year of regrinds.

To save energy: use of electric presses, eco-friendly practices, internal reduction plans, energy performance indicator, control and monitoring of consumption.

For safety: improvement of working conditions and QVCT (Quality of Life and Working Conditions) approach, active participation of employees in safety management, workstation studies, and prevention of MSDs.

Our certificates

An Integrated Management System with 3 ISO standards

ISO 9001 standard: quality management standard.

ISO 14001 standard: environmental management standard.

- ISO 45001 standard: occupational health and safety management standard.

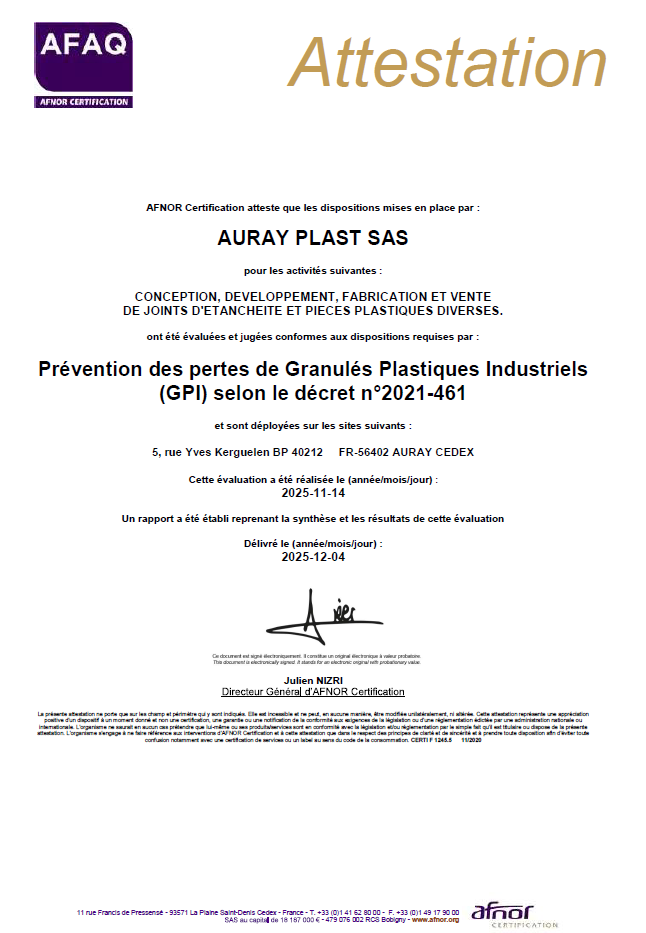

Audit GPI

As part of our approach to preventing and reducing environmental impact, the GPI (Granulés Plastiques Industriels) audit evaluates and reinforces our practices concerning the management and prevention of plastic granules. This audit aims to identify critical points in our manufacturing, storage and transport processes, in order to prevent any loss or spillage of granules into the environment.

Through this audit, we ensure that our facilities meet the highest standards of safety and cleanliness, by integrating equipment and protocols that minimize the risk of leaks. We are also increasing the awareness and training of our teams to ensure responsible and rigorous management at every stage of production.

Our commitment to this audit is in line with our desire to make an active contribution to preserving the environment, while meeting regulatory requirements and societal expectations in terms of sustainability and transparency.

Quality is primarily about beneficial and mutual relationships between customers and suppliers.

Fabrice BESNARD - QHSEE Manager

Références clients et témoignages