From idea to production "Made In France": Polyurethane (TPU) strap

Auray Plast supported Inwild in the production of its Polyurethane (TPU) straps. These robust straps are used in a wide range of leisure activities. They are used to securely fasten elements together.

The choice of material is a key factor in the straps use in extreme conditions.

Auray Plast helped Inwild find the right material. The material selected had to be resistant to torsion, elongation and UV rays. Several materials were analyzed to define the physicochemical properties required to meet the customer’s specifications.

A wonderful encounter between two French companies with a synergy and shared values sustainable and recyclable products made in France with local partners.

TPU, a technical material with many possibilities:

TPU is a material renowned for its high-performance properties. Some TPUs do not oxidize under UV light, making it one of the most stable coating compounds available for outdoor applications. Another advantage of TPU is its excellent resistance to hydrolysis and surface abrasion. This thermoplastic also retains resistance to low temperatures and solvents. These characteristics help to extend product life.

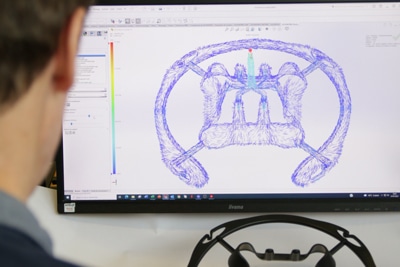

A rheological study to guarantee optimal injectability

The length of the strap and the viscosity of the material are factors to be taken into account when defining the number and position of injection points. Several rheological studies were carried out, as the product is available in 4 different lengths.

Injection channels have been optimized to ensure uniform filling and avoid air occlusion, which can lead to burns and visible weld lines. Mould set-up time has thus been optimized.

Mould design and development

Thanks to our mold-making partner, the engineering department designed a cost-optimized mold. The mold comprises several cavities, one for each strap length. This enabled us to design a single mold adapted to the press and production rates.

The mold was developed in 3 stages:

- The first parts come out of the mold and are analyzed.

- Functional stage: To be in the automatic mold cycle.

- Dimensional stage: Parts must conform to the drawing.

Discover the services of our design office

Our design office offers its expertise to provide you with technical services:

- Conducting injection mold tests

- Designing prototypes using 3D printing

- Verification and material testing for injection

- Creating grippers

- Rheological simulation and injectability.

Discover other episodes