Our engineering department can help you design technical parts using CAD (Computer-Aided Design). Thanks to our expertise in 3D modeling, we can transform your ideas into functional prototypes.

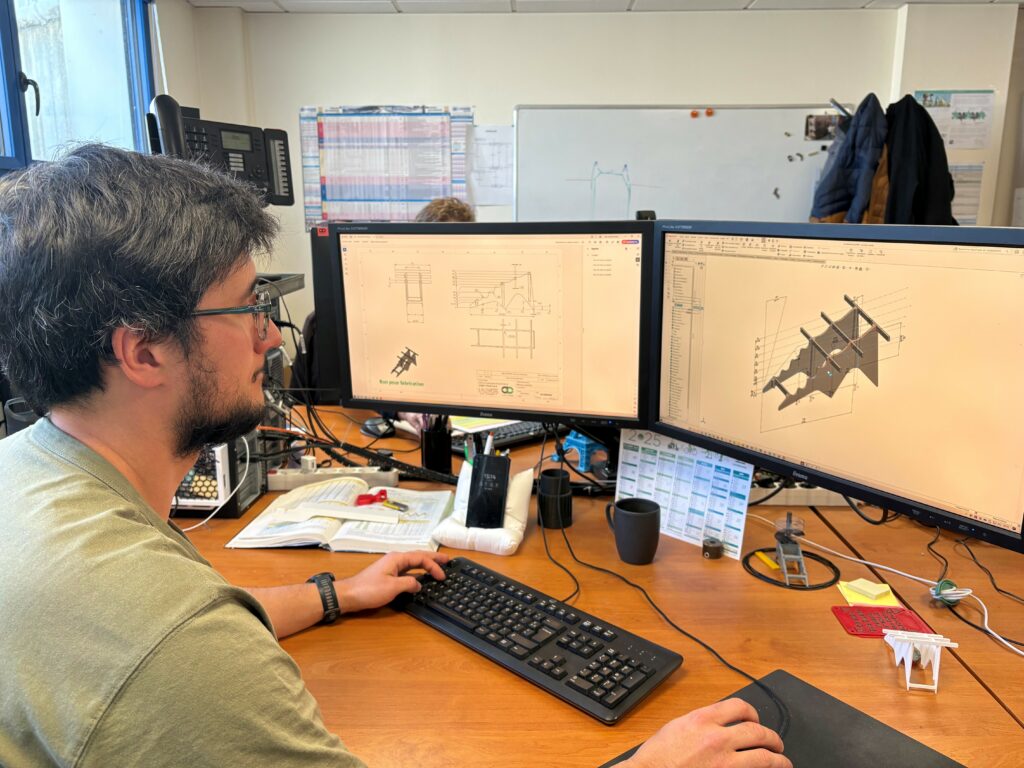

An integrated design office

Our engineering department analyzes your specifications and designs optimized solutions, taking into account technical, functional and economic constraints.

- 3D design and modeling: validation of shapes and dimensions.

- Materials analysis: choosing the right polymer for your application.

- Simulation: rheology (material flow), deformation, etc.

- Prototyping: 3D printing or injection molding, in small series.

Our commitment: combine innovation, technical feasibility and cost optimization to develop parts tailored to your needs.

Eco-design at the heart of our developments

As part of our sustainable development approach, we integrate eco-design right from the initial stages of part design. This involves choosing recycled or bioplastic materials, optimizing shapes to reduce material consumption and anticipating product end-of-life. We also work on optimizing production processes to limit waste and energy consumption. With this approach, we help our customers to combine industrial performance with environmental responsibility.

Co-development: for optimal collaboration

We place co-design at the heart of our approach, working hand-in-hand with our customers to bring them our expertise in thermoplastic injection molding. An injected part requires an optimized design for the injection process: functional design, undercuts, undercutting, thicknesses, choice of materials and industrial feasibility.

This collaborative approach reduces development times, anticipates any technical constraints and ensures efficient production in line with your requirements.

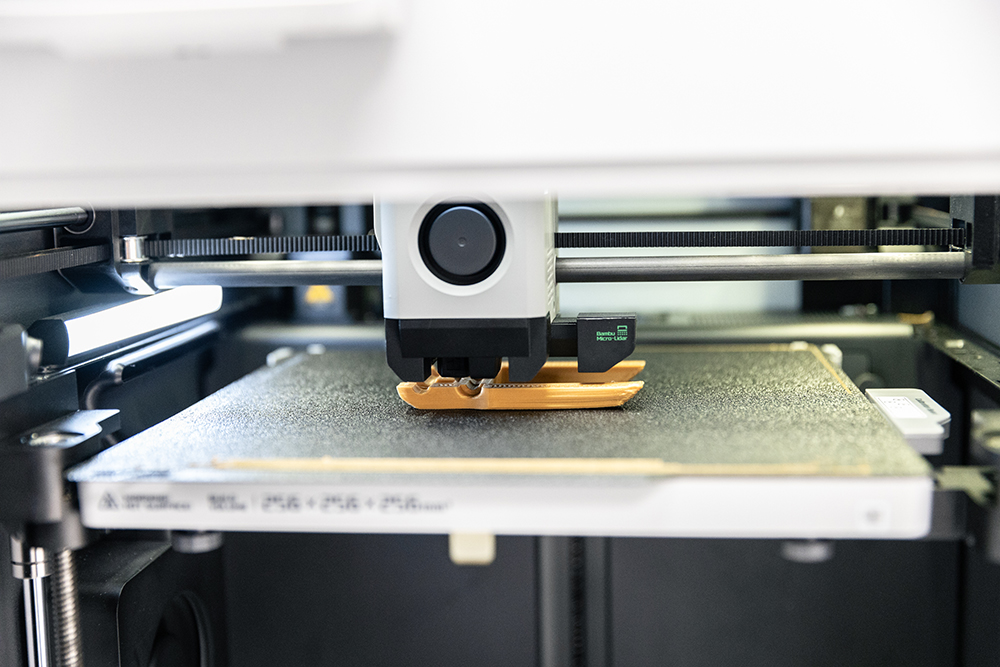

Prototyping: validate before you produce

Prototyping is an essential step in testing and validating a part before industrialization. Using 3D printing, we produce functional prototypes to check design, dimensions and mechanical resistance.

These tests enable us to optimize the design, anticipate possible adjustments and validate the transition to a prototype mold or launch industrialization. By integrating this phase upstream, we reduce costs and lead times, while ensuring that the design is perfectly adapted to manufacturing constraints.

Discover the services of our design office