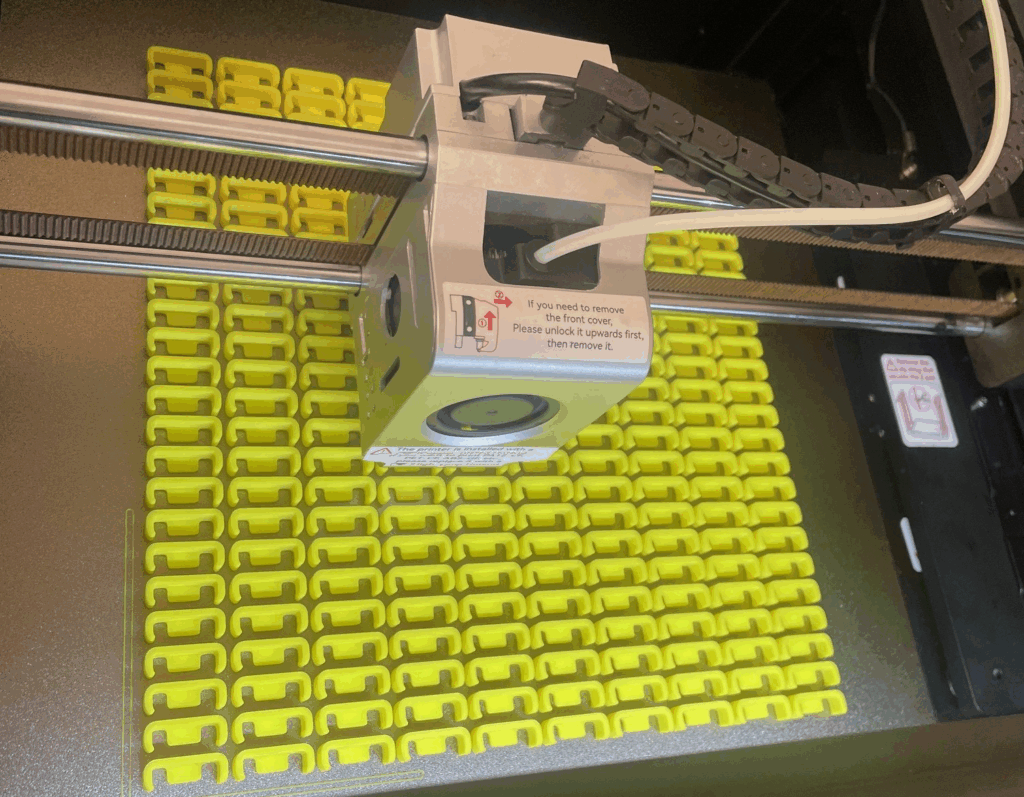

For some projects, small-scale production is a necessity. Whether for pre-production runs, functional tests or one-off requirements, 3D printing makes it possible to respond quickly and efficiently to these demands. It avoids the heavy investment involved in manufacturing a mold, and considerably reduces time-to-market..

3D printing: an agile solution for small quantities.

3D printing is particularly suited to production runs of 10 to 500 parts. It offers great flexibility in design, while maintaining satisfactory technical performance. Key benefits:- Reduced manufacturing lead times

- No tooling costs

- Files can be modified between runs

- Cost control for low volumes

A natural complement to plastic injection moulding

As a specialist in thermoplastic injection molding, we use 3D printing as a lever for responsiveness. This technology can be integrated into our global process to validate a design, produce a pre-production run or respond to a customer emergency, without blocking injection molding industrialization..

Frequently used applications :

- Pre-production runs

- Ergonomic or assembly testing

- Rapid restocking or troubleshooting

- Customized or personalized parts

Reliable, supervised production

We use professional printers and technical materials, chosen for their resistance and compatibility with industrial requirements. Each project is subjected to an upstream technical analysis to guarantee the quality of the parts produced.

Our team is with you from the design phase right through to delivery. If required, our engineering department can intervene to adapt or optimize your 3D files.

Discover the services of our design office