Auray Plast, produces new housings for AgriProTech

A project combining design and rheology

AgriProTech is a Breton company specializing in the design of sound repellents and solutions for scaring off undesirable bird and game species from sensitive crops and activities.

For this project, the Auray Plast design office assisted AgriProTech in the development of their housing:

- Study of specifications and sourcing

- Design and ergonomics

- Rheological study

- Mold design and fine-tuning

- Case industrialization

Support from the design office, from idea to industrialization

- Study of the project and compliance with specifications: the product must be UV-resistant and shock-resistant. To this end, an analysis of incoming materials was carried out in our characterization laboratory.

- Design and ergonomics, in parallel, work was initiated with a designer to adapt the case to the various technical components it contains. Particular care was taken with the design, so that the shield-shaped case would carry the company’s message and values. From an ergonomic point of view, an element protects the screen to facilitate user intervention.

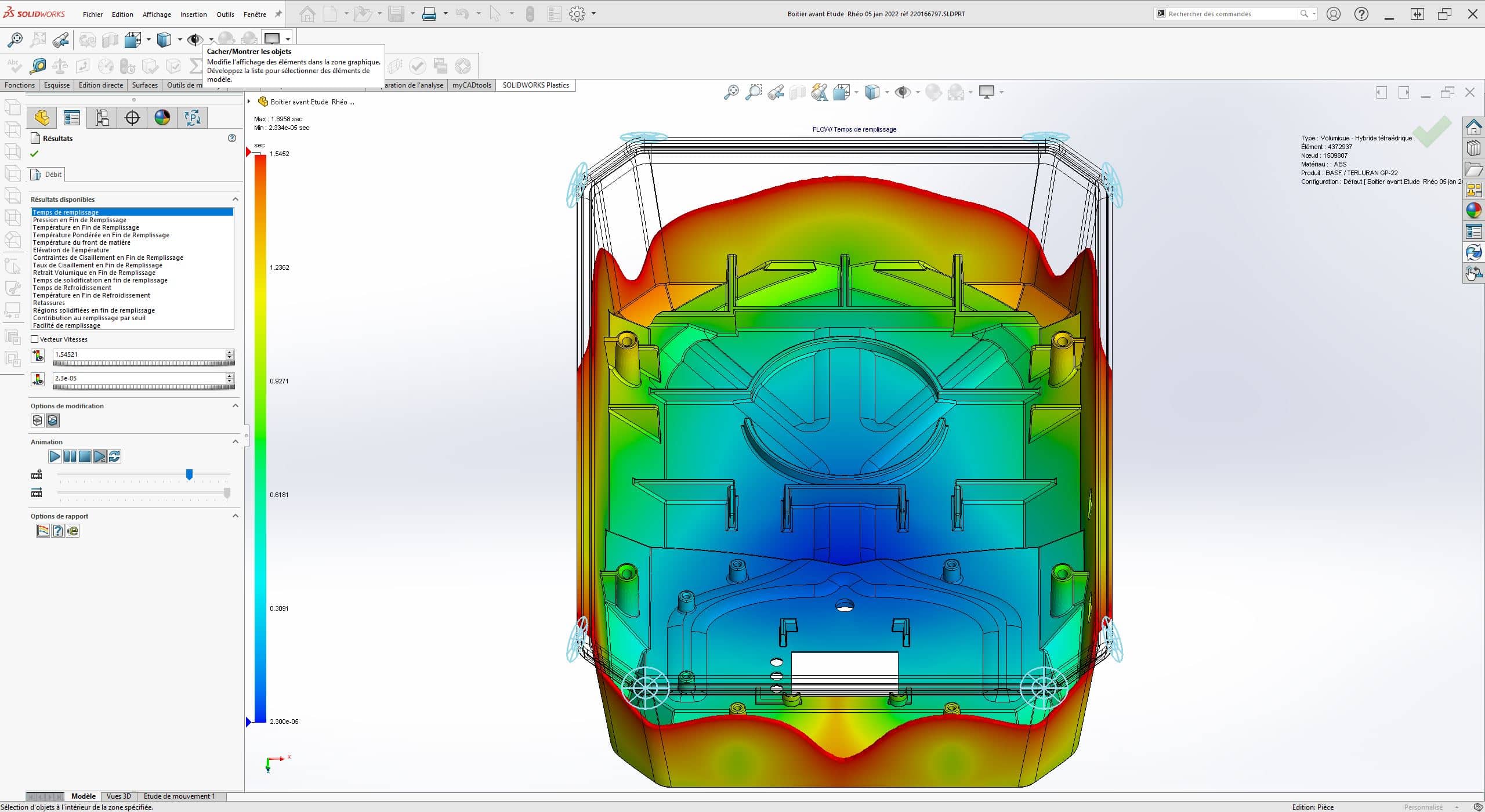

- A rheological study with numerical simulation to improve part performance and anticipate defects was carried out. This study enabled us to optimize the positioning of the injection point, create preferential filling zones and anticipate shaping processes.

- Creation of the mold with our moldmaking partners, with a compromise between mold complexity and material resistance. Mould development and parameterization.

- Industrialization of the case with a quality plan (color and dimensions).

This project is part of a 100% Breton collaboration with local players. The first cases were delivered just 12 weeks after the project was launched.

Discover the services of our design office

The design office puts its expertise at your disposal to offer you technical services:

- Injection mold testing

- Design of 3D printing prototypes

- Verification and testing of injection materials

- Production of gripping hands

- Rheological simulation & injectability