A new 100% automated assembly line

Robotization & performance

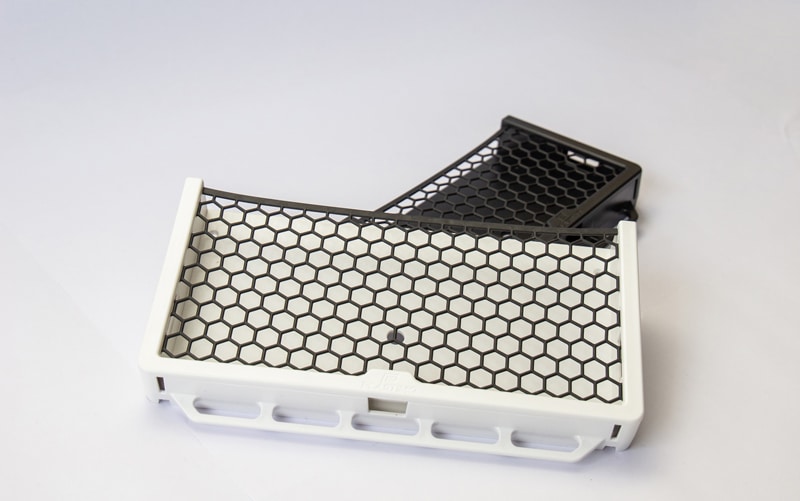

Continuous improvement and investment are necessary to ensure the long-term viability of the industry and its economic competitiveness. We have automated a production line by combining various functions on a single machine. 4 Fanuc 6-axis robots and 4 vision cameras are used to unscramble, check, cut, assemble and strap various components.

The aim of this project is to improve the logistical flow of the various components and the organization of production, as well as to organize stocks around the machine, while ensuring the ergonomics and accessibility of the workstation.

The results are increased productivity, improved quality, greater operator comfort and a reduction in musculoskeletal disorders.

Several training sessions were necessary to instruct the various employees in the machine’s programming. Auray Plast uses the machine 50% of the time, so there’s plenty of scope for you to entrust us with your assembly projects.

A 100% breton machine

“Effitech and Auray Plast worked very closely together. This project has enabled us to increase productivity, from 300 parts per hour to 400 parts per hour. Our main objective was to have a machine manufactured locally, particularly in Brittany, and to integrate a whole range of new technologies. One of the challenges of the project was to limit musculoskeletal disorders, because in manual work, in fact, employees were exposed to repetitive gestures. At the same time, we also worked on modifying containers and components to limit load-carrying and facilitate machine loading.”