Auray Plast supports its customers in the production of their plastic injection parts. Mould design is essential to guarantee a quality part. Our design office is with you every step of the way, to help you create a mold that meets your needs. The 5 key points :

1 - The part defines the mold

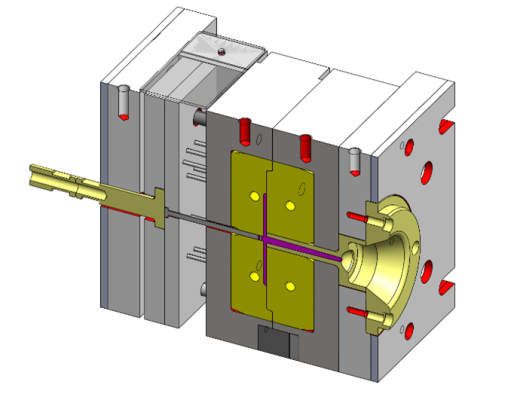

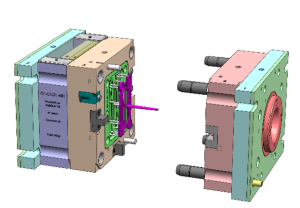

Thermoplastic injection molding is a manufacturing process in which a molten plastic material is injected into a mold at high pressure and temperature to produce a part with a complex shape.

C’est donc la pièce à injecter qui va définir le moule pour positionner le point d’injection, le plan de joint, les dépouilles et contre-dépouilles afin de définir la cinématique de l’outil.

Lorsque le moule se ferme la surface entre les deux parties est appelée plan de joint. C’est au niveau de ce plan de joint que la pièce devra se démouler. Il faut définir précisément sa position pour ne pas laisser de traces sur la pièce moulée. Les deux parties doivent s’emboiter parfaitement pour garantir l’étanchéité.

2 - A well-chosen material

The material is chosen according to the part’s application in terms of mechanical, UV and temperature resistance… We specialize in the transformation of TPU polyurethane, a material that is highly resistant to impact and abrasion. It can be colored and recycled.

Depending on the material, certain technical rules must be respected, particularly when it comes to demolding.

A part can only be demolded if its faces have a clearance angle, which varies according to the material used. Some parts may have an undercut (an angle opposite to the draft angle), rendering the part directly unmouldable.

3 - A well-optimized design is a guarantee of quality

The mold design must take account of technical constraints, such as the number of cavities, injection, cooling and ejection systems. CAD (computer-aided design) software is generally used for this step. Tool sizing must take into account part geometry, required tolerances, physicochemical properties of the material and production rates.

4 - Press selection: a key factor

It’s important to choose a press adapted to the shape and volume of the parts to be produced. The press must have sufficient clamping force to keep the mold closed during injection, as well as adequate capacity.

5 - Machining with quality in mind

The molds are then machined. Mould parts (such as cores, cavities, inserts, etc.) are manufactured with the utmost precision. The quality of mold manufacturing is essential to ensure part quality and optimize mold life.

The key is to have the right mold for the customer’s needs.

Mold maintenance

Cédric Le Diraison specializes in mold maintenance at Auray Plast. Injection mold maintenance is an essential step in guaranteeing the quality and durability of the parts produced. He acts as a link between the various departments: production, design office and subcontractors, with the aim of streamlining production processes.

He analyzes the various problems in order to find appropriate solutions, and proposes the necessary action plans.

These help prevent defects, breakages and loss of productivity. Counters are installed on the mold carriers to optimize the preventive plan. Injection mold maintenance involves cleaning, lubricating, inspecting and repairing mold components, according to a preventive or curative plan.

There are several types of injection mold maintenance, depending on the level of intervention and frequency required.

Thermoplastic injection molding glossary

- Parting line: contact surface between the two sides of the mold.

- Undercuts: angle of draft is the inclination of the mold walls required to facilitate part demolding.

Undercuts: when the shape of the part prevents direct demolding.

Kinematics: part of mechanics which studies movements as a function of time, without considering their causes.

Ejection: the ejection system is responsible for pushing the part out of the mold.

Injection point: point at which the material enters the mold cavity.

Thermoplastics: a thermoplastic is a material that softens when heated sufficiently, but then softens again when cooled. Examples of thermoplastics: TPU, POM , PA, PP, PEEK, ABS, ASA, PC, …