At Auray Plast, every project begins with close collaboration with our customers. Co-design transforms an idea into an industrializable product, while optimizing costs, lead times, and performance.

The customer’s need:

Specializing in lock protection, JAE2I consulted us to co-design a plastic protection that combines robustness, design, and mass production. Thanks to our expertise in tooling and plastic injection, we transformed this need into a concrete solution.

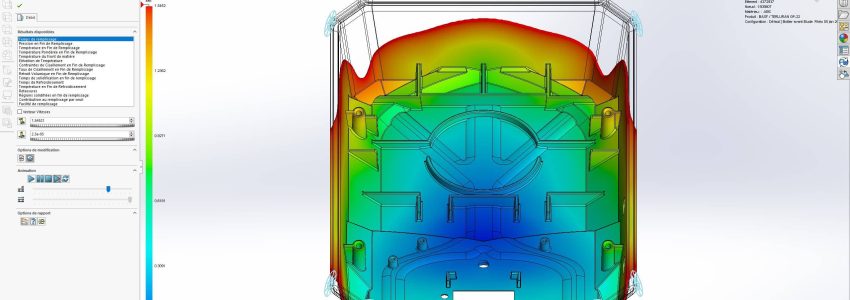

Our solution: technical focus; the 4-cavity mold

To meet the specifications, we developed a four-cavity mold, offering:

- simultaneous production of several variants

- reduced tooling costs

- accelerated time to market

Production optimization thanks to multi-cavity mold bases

The use of a single mold frame with multiple cavities allows different parts or variants to be produced simultaneously, while reducing costs and lead times. By combining several cavities in a single mold, the number of tools required is reduced, time to market is accelerated, and technical adjustments during mass production are facilitated.

From tooling to mass production

Once the mold and cavities have been approved, we provide:

- Plastic injection molding of parts

- Quality testing and adjustments

- Mass production in our workshops in Auray

Auray Plast tip

Integrating the four molds into a single mold has optimized the production cycle and reduced time to market.

Discover the other episodes