Our plastic engineering design and prototyping office

From co-design to industrialization

Our specialized plastic injection engineering office is composed of a multidisciplinary team of 5 engineers and technicians. They accompany you in a personalized manner by offering you technical solutions adapted to your specifications.

Our core business is to offer you a global approach to your project in a co-design process: material sourcing, design validation, prototyping, and testing.

Mastering the injection process perfectly, we can guide you in the industrialization of your technical parts to optimize your production on an industrial scale.

Our engineers will listen to you to design the plastic assemblies or sub-assemblies you need.

Innovation is an alliance between research, marketing, instinct, imagination, product, and industrial courage.

Our profession

Do you have a project, an idea? The design office can materialize it. A well-designed and optimized part is the starting point for a successful and industrializable project

Our method

Thinking about optimization and continuous improvement to create innovative design, reliable eco-designed parts in an economic and environmentally responsible logic.

Our philosophy

Exchanges and understanding of your needs as keystones to offer you relevant solutions in line with your specifications.

.

Collaborative co-design

Co-design, an innovative approach that includes several steps:

- Co-design, an innovative approach that includes several steps:

- Design o Co-design, an innovative approach that includes several steps:ptimization: study of mechanical constraints, rheology, and 3D modeling.

- Material sourcing: selection of raw materials and physicochemical studies.

- Prototyping: design validation to validate the function and industrialization.

Optimization-based industrialization

An essential step in thinking about your project on an industrial scale:

Material sourcing: selection of raw materials and physicochemical studies.

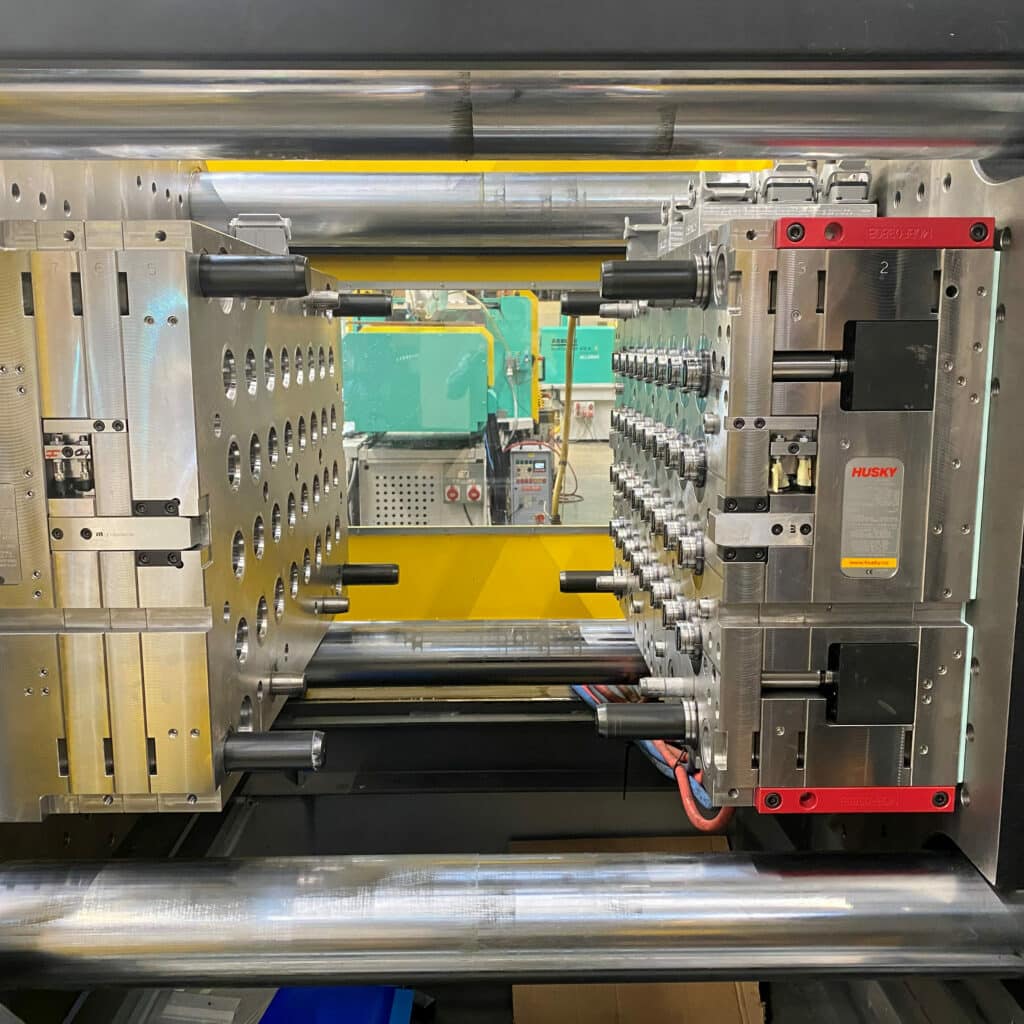

Mold testing: analysis of strengths and weaknesses, in-depth study of settings and possible improvements.

Tooling: a network of diversified mold makers, a guaranteed maintenance.

Prototyping: design validation to confirm function and industrialization.

The design office: our commitments

#We appreciate the challenge

At Auray Plast’s design office, we love a challenge and taking on the challenges proposed by our clients. Collaborative thinking, innovation, testing, and solving technical problems are part of our daily routine.

#We think about the environment

Because every action counts, we have integrated eco-design into our processes. Using fewer raw materials, saving resources, and working with local partners to limit environmental impact.

#We stay up to date with the latest innovations

Proposing innovative solutions for better performance is part of our DNA. For example, prototyping plastic injection parts in printed molds.

Discover the missions of the design office

Frédéric Landais and his team present the missions of the design office. Mold design, prototyping, 3D printing for the development of grippers with the goal of effectively meeting the needs of our clients.

Industrial drawing

Study and design of injected plastic parts

Study and design of injection molds

What I appreciate is the creative part, it's about meeting the clients' needs by imagining something they couldn’t.